Overview about productivity solution grant

Technology is not about fancy and expensive high-end solutions. You can kick-start your technology journey by taking simple steps to automate existing processes and improve productivity. The Productivity Solutions Grant (PSG) supports companies keen on adopting IT solutions and equipment to enhance business processes.

For a start, PSG covers sector-specific solutions including the retail, food, logistics, precision engineering, construction and landscaping industries. Other than sector-specific solutions, PSG also supports adoption of solutions that cut across industries, such as in areas of customer management, data analytics, financial management and inventory tracking.

These solutions have been pre-scoped by various government agencies such as Enterprise Singapore, National Environmental Agency (NEA) and Singapore Tourism Board (STB).

Food Manufacturing

Encrusting Machine

An encrusting machine is typically used in bakeries/ confectionaries to automate the bun-filling process. The machine can take a batch of dough, inject the filling, shape the bun and lay the final product out in trays ready for delivery.It is recommended for the Encrusting machine to allow manufacturing of large products up to 180g to allow for scalability

Rotary Wok Fryer

Rotary wok fryers significantly improve the industrial frying process by providing functions like automated heating, automated stirring. The rotary wok fryer is able to rotate and stir the food to ensure that the food is evenly cooked. Recommended min capacity of 20L to accomodate scalability

Automated Dough Filler/Depositor

An automatic depositor portions dough, fillings or batters onto moving or stationary lines. Portions will be of consistent size no matter who operates the machine.Also known as dough portion divider, the machine is made to suit the soft dough texture. As a guide, it is recommended for the Dough Filler to allow a divided dough weight of minimum 7gm and a dough dividing capacity with minimum 5 seconds

Automated Tray Sealer

The Automatic Tray Sealer requires employees to fill plastic trays with the product (eg. meat, buns, pasta) after which, the employee will place the trays in the equipment which will then be sealed by the film-like material

Commercial Inkjet Printer

Commercial inkjet printers integrated into the production lines are used to stamp information directly onto the product packaging. They allow the company to print specific information to individual product packets like bar codes, product information, expiry date. It is recommended for the Inkjet Printer to be able to integrate with the production line for a smoother flow of operation

Vacuum Packing and Sealing Machine

The vacuum packaging machine is used to vacuum seal products in a plastic wrap. Products already placed in plastic wrap loaded into the vacuum chambers, the product will be vacuum sealedThe alternative to this machine is for workers to manually seal products with cling packaging, without guarantees of a strong vacuum seal. It is recommended for the equipment to have a digital interface for ease of use

Form Fill Seal Machine

The form fill seal machine automates the packaging process. The product (e.g. noodles, flour) is placed at the hopper. It will funnel the product into the plastic packaging and heat seal the pack. The machine allows for quick and accurate filling in a manufacturing line.It is recommended for the form fill seal machine to have a touch panel interface and integrated printer for production information so as to allow smooth operation

Standalone Automated Industrial Utensil Washer

Automated standalone washer for pots, trays and utensils that replaces manual dishawashing. Compared to manual dishwashing, the automated washer gets the job done in less time while requiring less chemicals, energy and water

Rotary Oven

Oven with revolving racks that enables a ‘soft’ bake because of even heat distribution. Usually used for baked products that has a soft or fluffy texture, such as cakes, muffins, rolls and buns.Able to increase product yield by reducing amount of unevenly baked or burned cakes and muffins. Ideal for bakeries.For bigger rotary ovens, it is recommended for it to come with a trolley to load

Planetary or Spiral Mixer

Planetary/Spiral mixer are versatile industrial mixing equipment that can continuously produce large quantities of food products such as bread/cookie dough, cake batter, whipped toppings, icings, meringues and sauces.Available as floor-standing or tabletop model, and typically comes with interchangeable utensils such as a dough hook, mixing paddle and whisk. Ideal for companies dealing with soft food products.

Blast Freezer

Blast freezers chill food from cooking temperatures ~70 degrees to about -18 degrees within 240 min. Prevents growth of micro-organisms thereby improving food safety and reduces drip/water loss from freezing.Rapid freezing with blast freezer prevents formation of large ice crystals associated with normal freezers that reduces shelf life, quality and flavour of frozen food.It is recommended for the blast freezer to be able to be loaded with a trolley for ease of operation

General Food Manufacturing Equipment

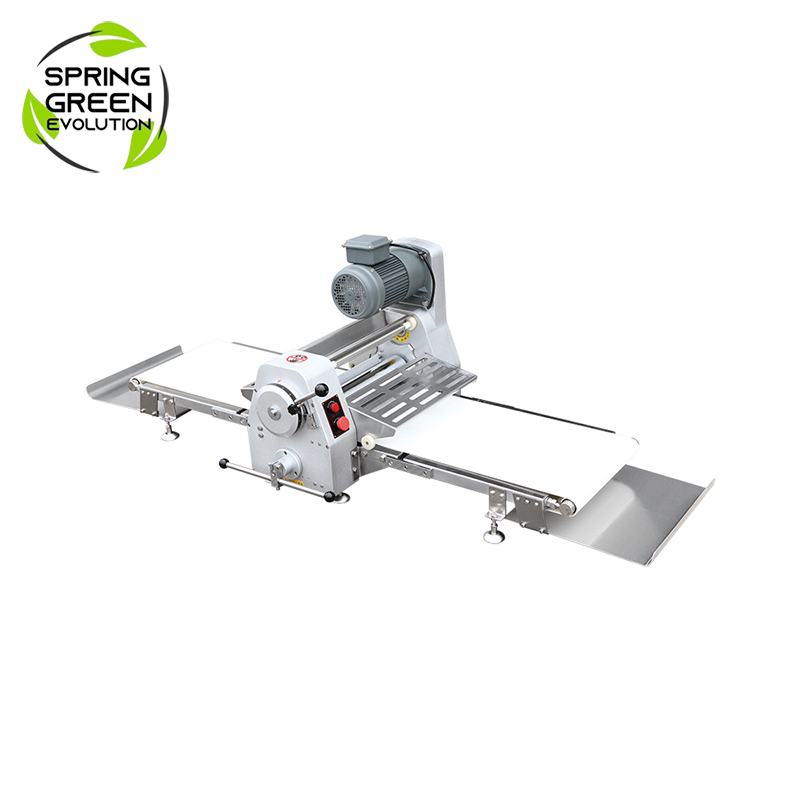

Dough Sheeter

Dough sheeter allows the sheeting and stretching of a variety of dough/products into different thickness. Examples of doughs/products include puff pastry, danish bread, croissant, pie, cookie, strudel, marzipan, pizza, fondant.The dough sheeter will allow pastry chefs to roll out dough to a specific thickness consistently in a short period of time. Grant support 80% of cost of equipment, up to $30,000 grant

Combi Oven

Combi oven can be programmed for convection, steam and combination cooking. Multi-functional cooking methods has a small footprint and can be used by F&B companies to cook and re-heat wide variety of food. Reduce kitchen workload as food can be cooked quickly with pre-set temperature, moisture and cooking time. Monitor browning and degree of doneness, reducing the need for repeated turning of pan-fried dishes.Grant support 80% of cost of equipment, up to $30,000 grant

Eligibility Criteria

Applicants must meet the following eligibility criteria at the point of application:

a) must be registered in Singapore

b) purchase/lease of the IT solution or equipment or consultancy service must be used in Singapore

c) must not have:

Made any payment to a supplier, vendor or third party in relation to the purchase/lease of the IT solution or equipment or consultancy service

Signed any contract with a supplier, vendor or third party in relation to the purchase/lease of the IT solution or equipment or consultancy service

Please refer to ‘Things to Note’ for additional requirements.

Customer Support

For more information about PSG Grant for Food Manufacturing products, please contact us at:

Spring Green Evolution Pte Ltd

Showroom: 66 Tannery Lane, Sindo Building, #04-09. S347805

Telephone/WhatsApp: (+65) 88914519. Email: info@sgesg.com

Facebook: www.facebook.com/SGEsg

Website: www.sgesg.com

Hi sir,

I am interested in your AW02 auto weighing & filling machine. Is there a PSG grant for food manufacturer ?

Is there any aftersales service & spare parts support to Singapore customers ?

Kind Regards,

Vincent Tan